Chromatography

CTC GC AS syringes with fixed needles

| Volume [µl] | Needle length [mm] | Gauge | Needle ID [mm] | Tip | Gastight |

|---|---|---|---|---|---|

| 5 | 50 | 26 | 0.1 | Cone | × |

| 5 | 50 | 23 | 0.11 | Cone | × |

| 5 | 50 | 26 | 0.11 | Cone | × |

| 10 | 50 | 26 | 0.11 | Cone | yes |

| 10 | 50 | 26 | 0.15 | Cone | × |

| 10 | 50 | 26 | 0.11 | Cone | × |

| 10 | 50 | 23 | 0.11 | Cone | × |

| 10 | 50 | 22 | 0.175 | Single hole | yes |

| 10 | 50 | 23 | 0.11 | Cone | × |

| 25 | 50 | 26 | 0.11 | Cone | yes |

| 25 | 50 | 26 | 0.15 | Cone | × |

| 25 | 50 | 23 | 0.24 | Cone | yes |

| 100 | 50 | 26 | 0.11 | Cone | yes |

| 100 | 50 | 23 | 0.24 | Cone | yes |

| 250 | 50 | 26 | 0.25 | Cone | yes |

| 500 | 50 | 26 | 0.25 | Cone | yes |

| 1000 | 56 | 26 | 0.15 | Single hole | yes |

| 1000 | 56 | 23 | 0.15 | Single hole | yes |

| 2500 | 56 | 26 | 0.15 | Single hole | yes |

| 2500 | 56 | 23 | 0.15 | Single hole | yes |

Agilent GC AS syringes with removable needles

| Volume [µl] | Needle length [mm] | Gauge | Tip | Gastight |

|---|---|---|---|---|

| 0.5 | 42 | 26 | Cone | × |

| 0.5 | 42 | 23 | Cone | × |

| 0.5 | 42 | 23-26 | Cone | × |

| 1 | 42 | 23 | Cone | × |

| 5 | 42 | 26 | Cone | × |

| 5 | 42 | 23 | Cone | × |

| 5 | 42 | 23-26 | Cone | × |

| 10 | 42 | 26 | Cone | × |

| 10 | 42 | 23 | Cone | × |

| 10 | 42 | 26 | Cone | yes |

| 10 | 42 | 23 | Cone | yes |

| 10 | 42 | 23-26 | Cone | × |

| 10 | 42 | 23-26 | Cone | yes |

| 25 | 42 | 23 | Cone | × |

| 50 | 42 | 23 | Cone | × |

| 100 | 42 | 23 | Cone | × |

| 250 | 42 | 23 | Cone | × |

Agilent GC AS syringes with fixed needles

| Volume [µl] | Needle length [mm] | Gauge | Tip | Gastight |

|---|---|---|---|---|

| 5 | 42 | 26 | Cone | × |

| 5 | 42 | 23 | Cone | × |

| 5 | 42 | 23-26 | Cone | × |

| 10 | 42 | 26 | Cone | × |

| 10 | 42 | 23 | Cone | × |

| 10 | 42 | 23 | Cone | yes |

| 10 | 42 | 23-26 | Cone | × |

| 10 | 42 | 23-26 | Cone | yes |

| 25 | 42 | 23-26 | Cone | yes |

| 50 | 42 | 23-26 | Cone | yes |

| 100 | 42 | 23-26 | Cone | yes |

Official methods using immunoafinity columns

List of the Official methods using that can be used with VICAM immunoaffinity columns

| Official Method | Mycotoxin | Date of Issue | Method |

|---|---|---|---|

| EN - 12955 | Aflatoxin | July 1999 | Foodstuffs - Determination of aflatoxin B1, and the sum of aflatoxins B1, B2, G1 and G2 in cereals, shell-fruits and derived products - High performance liquid chromatographic method with post column derivatization and immunoaffinity column clean up |

| EN - 14123 | Aflatoxin | January 2008 | Foodstuffs - Determination of aflatoxin B1, and the sum of aflatoxins B1, B2, G1 and G2 in hazelnuts, peanuts, pistachios, figs, and paprika powder - High performance liquid chromatographic method with post column derivatization and immunoaffinity column clean up |

| EN - 14132 | Ochratoxin A | 2009 | Foodstuffs - Determination of ochratoxin A in barley and roasted coffee - HPLC method with immunoaffinity column clean-up |

| EN - 14133 | Ochratoxin A | July 2003 | Foodstuffs - Determination of ochratoxin A in wine and beer - HPLC method with immunoaffinity column clean-up |

| EN - 14352 | Fumonisin | July 2004 | Foodstuffs - Determination of fumonisin B1 and B2 in maize based foods - HPLC method with immunoaffinity column clean-up |

| EN ISO 14501 | Aflatoxin | 2007 | Milk and milk powder - Determination of aflatoxin M1 content - Clean-up by immunoaffinity chromatography and determination by high-performance liquid chromatography |

| EN - 15829 | Ochratoxin A | 2010 | Foodstuffs - Determination of ochratoxin A in currants, raisins, sultanas, mixed dried fruit and dried figs. HPLC method with immunoaffinity column cleanup and fluorescence detection |

| EN - 15835 | Ochratoxin A | 2010 | Foodstuffs - Determination of ochratoxin A in cereal based foods for infant and young children. HPLC method with immunoaffinity column cleanup and fluorescence detection |

Rxi-35sil MS

Rxi® Capillary GC Columns

These columns have been designed specifically to be the best columns available, for exceptional inertness, ultra-low bleed, and reproducible retention and selectivity. In addition to outstanding performance, this combination of column characteristics assures Rxi® columns will have long lifetimes. The Restek chemists also have developed a stable, reproducible manufacturing process, so that Rxi® columns will meet your needs every time you install a new column.

Benefits of Rxi® columns

- Ultra-low bleed

- Exceptional inertness

- Reproducible performance, column after column

Applications

- Organochlorine pesticides

- PCB congeners or Aroclor mixes

- Herbicides

- Pharmaceuticals

- Sterols

- Rosin acids

- Phtalate esters

| ID (mm) | df(µm) | Temperature limits (°C) |

|---|---|---|

| 0.25 | 0.25 | -60 to 340/360 |

| 0.32 | 0.25 | -60 to 340/360 |

| 0.53 | 0.50 | -60 to 320/340 |

Rxi-624Sil MS

Rxi® Capillary GC Columns

These columns have been designed specifically to be the best columns available, for exceptional inertness, ultra-low bleed, and reproducible retention and selectivity. In addition to outstanding performance, this combination of column characteristics assures Rxi® columns will have long lifetimes. The Restek chemists also have developed a stable, reproducible manufacturing process, so that Rxi® columns will meet your needs every time you install a new column.

Benefits of Rxi® columns

- Ultra-low bleed

- Exceptional inertness

- Reproducible performance, column after column

The Rxi®-624Sil MS stationary phase

- Excellent peak shape for a wide range of compounds, including acidic and basic compounds.

- Highly selective for residual solvents, great choice for USP<467>.

Applications

- Residual Solvents

| ID (mm) | df(µm) | Temperature limits (°C) |

|---|---|---|

| 0.18 | 1.00 | -60 to 300/320 |

| 0.25 | 1.40 | -60 to 300/320 |

| 0.32 | 1.80 | -60 to 300/320 |

| 0.53 | 3.00 | -60 to 280/300 |

Rxi-5 HT

Rxi® Capillary GC Columns

Rxi® Capillary GC Columns

These columns have been designed specifically to be the best columns available, for exceptional inertness, ultra-low bleed, and reproducible retention and selectivity. In addition to outstanding performance, this combination of column characteristics assures Rxi® columns will have long lifetimes. The Restek chemists also have developed a stable, reproducible manufacturing process, so that Rxi® columns will meet your needs every time you install a new column.

Benefits of Rxi® columns

- Ultra-low bleed

- Exceptional inertness

- Reproducible performance, column after column

- 40% longer lifetime from specially designed fused silica tubing

- Columns processed for high temperature applications

Applications

- Diesel Fuels

- Motor Oils

- High Boiling Petroleum Products

- Polymers/Plastics

- High Molecular Weight Waxes

- Simulated Distillation Methods

- Long-chained Hydrocarbons

- Triglycerides

| ID (mm) | df(µm) | Temperature limits* (°C) |

|---|---|---|

| 0.25 | 0.10 | -60 to 400 |

| 0.25 | 0.25 | -60 to 400 |

| 0.32 | 0.10 | -60 to 400 |

| 0.32 | 0.25 | -60 to 400 |

| 0.53 | 0.15 | -60 to 400 |

* Column is capable of going to 430°C, but column lifetime will be reduced.

Particle size conversion

| Mesh size (No.) | Metric size (µm) | Nominal opening (inches) |

|---|---|---|

| 40 | 420 | 0.0165 |

| 45 | 354 | 0.0139 |

| 50 | 297 | 0.0117 |

| 60 | 250 | 0.0098 |

| 70 | 210 | 0.0083 |

| 80 | 177 | 0.0070 |

| 100 | 149 | 0.0059 |

| 120 | 125 | 0.0049 |

| 140 | 105 | 0.0041 |

| 170 | 88 | 0.0035 |

| 200 | 74 | 0.0029 |

| 230 | 63 | 0.0025 |

| 270 | 53 | 0.0021 |

| 325 | 44 | 0.0017 |

| 400 | 37 | 0.0015 |

HPLC troubleshooting

Abnormal pressure

No pressure reading, no flow

| Possible cause | Solution |

|---|---|

| Power off | Turn on power |

| Fuse blown | Replace fuse |

| Controller setting or failure | Verify proper settings, repaire or replace controller |

| Broken piston | Replace piston |

| Air trapped in pump head | Degas mobile phase, bleed air from pump and prime pump |

| Insufficient mobile phase | Replenish reservoir, replace inlet frit if it is blocked |

| Faulty check valves | Replace check valves |

| Major leak | Tighten or replace fittings |

Now pressure reading, flow is normal

Now pressure reading, flow is normal

| Possible cause | Solution |

|---|---|

| Faulty meter | Replace meter |

| Faulty pressure transducer | Replace transducer |

High back pressure

| Possible cause | Solution |

|---|---|

| Flow rate set too high | Adjust settings |

| Blocked column frit | Backflush column if it is permitted, replace frit according to the manufacturer's instructions and warratny conditions or replace column |

| Improper mobile phase, precipitated buffer | Use correct mobile phase, wash column |

| Improper column | Use proper column |

| Injector blockage | Clear blockage or replace injector |

| Column temperature too low | Raise temperature |

| Controller malfunction | Repair or replace controller |

| Blocked guard column | Remove/replace guard column |

| Blocked in-line filter | Remove/replace in-line filter |

You should find out, what caused high back pressure - column or system? We recommend following procedure:

Remove column from the system and turn on pump. If high back pressure still appears, then the blockage is in the system:

- blocked or crimped tubing

- dirty pump frit

- or clogged injection valve

If the pressure is normal, there is a problem with the column:

- clogged or damaged pre-column filter, guard column or frit

- precipitation of sample or buffer in column

Low back pressure

| Possible cause | Solution |

|---|---|

| Flow set too low | Adjust flow rate |

| Leak in the system | Locate and correct |

| Improper column | Use proper column |

| Column temperature too high | Lower temperature |

| Controller malfunction | Repair or replace controller |

Fluctuating pressure

See section High back pressure.

Pressure dropping to zero

See sections No pressure reading, no flow and No pressure reading, flow is normal

Pressure dropping, but not to zero

See section Low pressure

Pressure cycling

| Possible case | Solution |

|---|---|

| Air in pump | Degas solvent and/or bleed air from the pump |

| Faulty check valve(s) | Replace check valve(s) |

| Pump seal failure | Replace pump seal |

| Insufficient degassing | Degas solvent and/or change degassing methods (e.g. use vacuum degasser) |

| Leak in system | Locate leak and correct it |

| Using gradient elution | Pressure cycling is normal due to viscosity change |

Leaks

Leaks are usually stopped by tightening or replacing a fitting. Be aware, however, that overtightened metal compression fittings can leak and plastic fingertight fittings can wear out. If a fitting leak does not stop when the fitting is tightened a little, take the fitting apart and inspect for damage (e.g. distored ferrule, or particles on the sealing surface). If the fitting or ferrule is damaged, replace it with new one.

Leaky fittings

| Possible cause | Solution |

|---|---|

| Loose fitting | Tighten the fitting |

| Stripped fitting | Replace the fitting |

| Overtightened fitting | Loosen and retighten the fitting. If the fitting is damaged, replace it. |

| Dirty fitting | Disassemble fitting and clean it. If the fitting is damaged, replace it. |

| Mismatched parts | Use all parts from the same brand/type. |

Leaks at the pump

| Possible cause | Solution |

|---|---|

| Loose check valves | Tighten check valve (do not overtighten) or replace check valve |

| Loose fittings | Tighten fittings (do not overtighten) |

| Mixer seal failure | Repair or replace |

| Pump seal failure | Repair or replace the seal |

| Pulse damper failure | Replace pulse damper |

| Proportionin valve failure | Check diaphragms, replace if leaky and/or check for fitting damage, replace |

| Purge valve | Tighten valve or replace it if it is faulty |

Injector leaks

| Possible cause | Solution |

|---|---|

| Rotor seal failure | Rebuild or replace rotor |

| Blocked loop | Clean or replace loop |

| Loose injector port seal | Adjust |

| Improper syringe needle diameter | Use correct syringe |

| Waste line siphoning | Keep waste line above surface vaste, with proper slope |

| Waste line blockage | Replace waste line |

Column leaks

| Possible cause | Solution |

|---|---|

| Loose endfitting | Tighten endfitting |

| Column packing in ferrule | Disassemble, rinse ferrule, reassemble |

| Improper frit thickness | Use proper frit(*) |

*Note: When the particle size of stationary phase is 3 to 4 µm, use frit 0.5 µm. When particle size of stationary phase is 5 to 20 µm, use frit 2 µm.

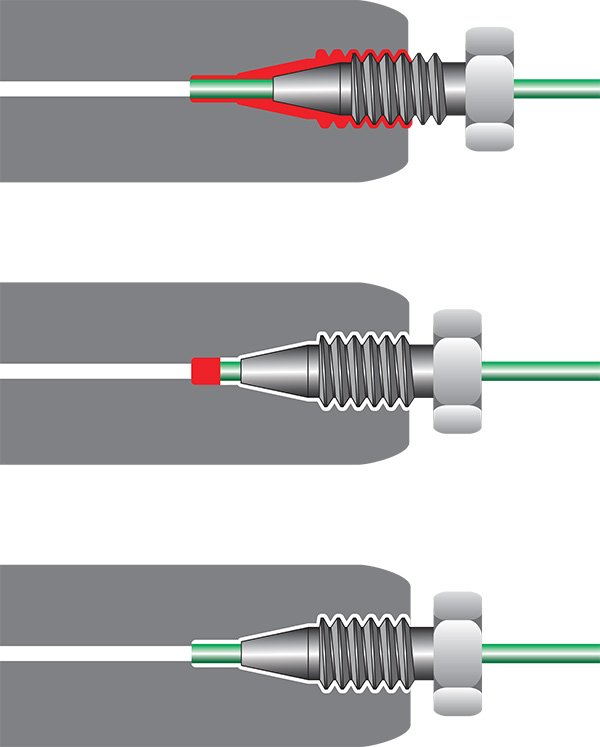

Picture: Correct fitting/capillary connection (dead volume in red)

Detector leaks

| Possible cause | Solution |

|---|---|

| Cell gasket failure | Prevent excessive backpressure or replace gasket |

| Cracked cell window(s) | Replace cell window(s) |

| Leaky fittings | Tighten or replace fittings |

| Blocked waste line | Replace waste line |

| Blocke flow cell | Rebuild or replace flow cell |

Problems with the chromatogram

Many issues in the LC system appear as changes in the chromatogram. Some of these can be solved by changes in the instrument, however, other problems require modification of the assay procedure. Setting the proper column type, pre-column or guard column, tubings, detector cell and mobile phase are keys to good chromatography.

Peak tailing

| Possible cause | Solution |

|---|---|

| Blocked frit | Reverse flush column (if it is allowed) or replace frit (if it is allowed) or replace column |

| Column void | Fill void |

| Interfering peak | Use longer column or change mobile phase and/or column selectivity |

| Wrong mobile phase pH | Adjust pH. For basic compounds, lower pH usually provides more symmetric peaks |

| Sample reacting with active sites | Add ion pair reagent or volatile basic modifier or change column |

Peak fronting

| Possible cause | Solution |

|---|---|

| Low temperature | Increase column temperature |

| Wrong sample solvent | Use mobile phase for injection solvent |

| Sample overload | Decrease sample concentration |

| Bad column | Reverse flush column (if it is allowed) or replace inlet frit (if it is allowed) or replace the column. |

Split peaks

| Possible cause | Solution |

|---|---|

| Contamination on guard or analytical column inlet | Remove guard column and attempt analysis. replace guard column if necessary. If analytical column is obstructed, reverse and flush (if it is allowed). If problem persists, column may be fouled with strongly retained contaminants. Use appropriate restoration procedure (see column care information). If problem persists, inlet is probably plugged. Change frit or replace column. |

| Sample solvent incompatible with mobile phase | Change solvent. whenever possible, inject samples in mobile phase. |

Distortion of larger peaks

The peak distortion can be caused by sample overload. Reduce the sample size.

Distortion of early peaks

The distortion of early eluting peaks can be caused by wrong injection solvent. Reduce the injection volume, or use weaker injection solvent.

Tailing, early peaks mor than later ones

| Possible cause | Solution |

|---|---|

| Extra-column effects | Replumb the system (shorter, narrower tubing), use smaller volume detector cell |

Increased tailing as k' increases

| Possible cause | Solution |

|---|---|

| Secondary retention effects, reversed-phase mode | Add triethylamine (basic sampes) or add acetate (acidic samples) or add salt or buffer (ionic samples) or try a different column. |

| Secondary retention effects, normal-phase mode | Add triethylamine (basic compounds) or add acetic acid (acidic compounds) or add water (poly-functional compounds). Only for normal-phase methods which use water-miscible solvents. You can also try a different LC method. |

| Secondary retention effects, ion-pair chromatography | Add triethylamine (basic samples) |

Acidic or basic peaks tail

| Possible cause | Solution |

|---|---|

| Inadequate buffering | Use 50 to 100 mM buffer concentration, use buffer with pKa equal to pH of mobile phase |

Extra peaks

| Possible cause | Solution |

|---|---|

| Ghost peaks | Impurities in the sample, reagents or material used. Change clean-up procedure and/or check possible source of contamination (glassware, vials, used reagents, solvents, etc...) |

| Late eluting peak from previous injection | Increase run time or gradient slope and/or increase flow rate |

Retention time drifts

| Possible cause | Solution |

|---|---|

| Poor temperature control | Use column termostat. If you use it, check its proper functionality. |

| Mobile phase changing | Prevent change (evaporation, reaction, etc...) |

| Poor column equilibration | Allow more time for column equilibration between runs |

Abrupt retention time changes

| Possible cause | Solution |

|---|---|

| Flow rate change | Reset flowrate |

| Air bubble in pump | Bleed air from pump |

| Improper mobile phase | Replace mobile phase with proper one and/or set proper mobile phase mixture on controller |

Baseline drift

| Possible cause | Solution |

|---|---|

| Column temperature fluctuation. Even small changes cause cyclic baseline rise and fall. Most often affects refractive index, UV and conductivity detectors at high sensitivity | Control column and mobile phase temperature, use heat exchanger before detector |

| Nonhomogenous mobile phase. Baseline drift is usually to higher absorbance, rather than cyclic pattern from temperature fluctuation. | Use HPLC grade solvents, high purity salts, and additives. Degas mobile phase before use, sparge with helium during use. |

| Contaminant or air buildup in detector cell | Flush cell with methanol or other strong solvent. If necessary, clean cell with 1N HNO3 (never use HCl). |

| Plugged outlet line after detector. High pressure cracks cell windoe, producing noisy baseline. | Unplug or replace line. Refere to detector manual to replace window. |

| Mobile phase mixing problem or change in flow rate | Correct composition or flow rate. To avoid this issue, routinely monitor composition and flow rate. |

| Slow column equilibration, especially when changing mobile phase | Flush with intermediate strength solvent, run 10 to 20 column volumes of new mobile phase before analysis |

| Mobile phase contaminated, deteriorated or prepared from low quality materials | Chack mobile phase preparation. Use highest grade chemicals and HPLC solvents |

| Strongly retained materials in sample (high k') can elute as very broad peaks and appear to be a rising baseline (gradient analyses canaggravate problem). | Use guard column. If necessary, flush column with strong solvent between injections or periodically during analysis. |

| Mobile phase recycled but detector not adjusted | Reset baseline. Use new mobile phase when dynamic range of detector is exceeded. |

| Detector (UV) not set at absorbance maximum but at slope of curve | Change wavelength to UV absorbance maximum |

Baseline noise (regular)

| Possible cause | Solution |

|---|---|

| Air in mobile phase, detector cell or pump | Degas mobile phase. Flush system to remove air from detector cell or pump. |

| Leak | See section Leaks. Check system for loose fittings. Check pump for leaks, salt build-up, unusual noise. Change pump seals if necessary. |

| Incomplete mobile phase mixing | Mix mobile phase by hand or use less visous sample. |

| Temperature effect (column at high temperature or detector unheated) | Reduce differential or add heat exchanger |

| Other electronic equipment on the same line | isolate LC, detector or recorder/PC to determine if source of issue is external. Correct as necessary. |

| Pump pulsation | Incorporate pulse dampener into system. |

Baseline noise (irregular)

| Possible cause | Solution |

|---|---|

| Leak | See section Leaks. Check system for loose fittings. Check pump for leaks, salt build-up, unusual noise. Change pump seals if necessary. |

| Mobile phase contaminated, deteriorated or prepared from low quality materials | Check mobile phase preparation |

| Mobile phase solvents immiscible | Select and use only miscible solvents |

| Air trapped in system | Flush system with strong solvent |

| Air bubbles in detector | Purge detector. Install back-pressure device after detector |

| Detector/recorder electronics | Isolate detector and recorder/PC electronically. Refer to isntruction manual to correct problem. |

| Detector cell contaminated (even small amounts of contaminants can cause noise) | Clean cell by flushing 1N HNO3 (never use HCl) |

| Weak detector lamp | Replace lamp |

| Column leaking silica or packing material | Replace column |

| Mobile phase mixer inadequate or malfunctioning | Repair or replace the mixer or mix off-line if isocratic. |

Broad peaks

| Possible cause | Solution |

|---|---|

| Mobile phase composition changed | Prepare new mobile phase |

| Mobile phase flow rate too low | Adjust flow rate |

| Leaks (especially between column and detector) | See section Leaks. Check system for loose fittings. Check pump for leaks, salt build-up, unusual noise. Change pump seals if necessary. |

| Detector settings are incorrect | Adjust settings |

| Buffer concentration too low | Increase buffer concentration |

| Guard column contaminated/worn out | Replace guard column |

| Column contaminated/worn out. Low plate number. | Replace column with new one of same type. |

| Void at column inlet | Open inlet end and fill void or replace column |

| Peak represents two or more poorly resolved compounds | Change column type to improve separation |

| Column temperature too low | Increase temperature. Do not exceed 60°C unless higher temperatures are acceptable to column manufacturer. |

| Detector time constant too large | Use smaller time constant |

Broad peaks can be caused by extra-column effects:

Broad peaks can be caused by extra-column effects:

- Column overloaded - inject smaller volume (e.g. 10µl instead of 100µl) or dilute sample

- Detector response time or cell volume too large - reduce response time or use smaller cell

- Tubing between column and detector too long ir ID too large - use as short a piece of 0.007" to 0.010" ID tubing as practical (UHPLC techniques require use of 0.005" ID tubing)

- Recorder response time too high - Reduce response time

Loss of resolution

| Possible cause | Solution |

|---|---|

| Mobile phase contaminated(deteriorated (causing retention time to change) | Prepare new mobile phase |

| Obstructed guard or analytical column | Remove guard column and attepmt analysis. Replace guard if necessary. If analytical column is obstructed, reverse and flush. If problem persists, column may be fouled with strongly retained contaminants. Use appropriate restoration procedure according to the manufacturer's manual. If problem persists, inlet is probably plugged. Change frit or replace column. |

All peaks too small

| Possible cause | Solution |

|---|---|

| Detector attenutation too high | Reduce attenuation |

| Detector time constant too large | Use smaller time constant |

| Injection size too small | Increase sample concentration or increase injection volume, if column size allows it |

| Improper recorder connection | Use correct connection |

All peaks too large

| Possible cause | Solution |

|---|---|

| Detector attenuation too low | Use larger attenuation |

| Injection size too large | Reduce sample concentration or decrease injection volume, use smaller sample loop or use partial loop filling |

| Improper recorder connection | Use correct connection |

Problems with the injector

Manual injector, hard to turn

| Possible cause | Solution |

|---|---|

| Damaged rotor seal | Rebuilt or replace seal/valve |

| Rotor too tight | Adjust rotor tension |

Manual injector, hard to load

| Possible cause | Solution |

|---|---|

| Valve misaligned | Adjust alignment |

| Blocked loop | Replace loop |

| Dirty syringe | Clean or replace syringe |

| Blocked lines | Clear or replace lines |

Autosampler injector - won't turn

| Possible cause | Solution |

|---|---|

| No air pressure or power | Supply proper pressure/power |

| Rotor too tight | Adjust |

| Valve misaligned | Adjust alignment |

Autosampler - other problems

| Possible cause | Solution |

|---|---|

| Blockage | Clear or replace blocked portion |

| Jammed mechanism | See service manual |

| Faulty controller | Repair or replace controller |

Problems detected by smell, sight or sound

Solvent smell

| Possible cause | Solution |

|---|---|

| Leak | See section Leaks |

| Spill | Check for overflowing waste container or locate spill and clean up |

"Hot" smell

| Possible cause | Solution |

|---|---|

| Overheating module | Check for proper ventilation, adjust it or check temperature setting, adjust or shut module off, see service manual |

Abnormal meter readings

| Possible cause | Solution |

|---|---|

| Pressure abnormality | See section Abnormal pressure |

| Column oven problem | Check settings and adjust, see service manual |

| Detector lamp failing | Replace lamp |

Warning lamps

| Possible cause | solution |

|---|---|

| Pressure limit exceeded | Check for blockage or check limit settings and adjust them |

| Other warning lamps | See operation/service manual |

Warning buzzers

| Possible cause | Solution |

|---|---|

| Solvent leak/spill | Locate and correct |

| Other warning buzzers | See operation/service manual |

Squeaks and squeals

| Possible cause | Solution |

|---|---|

| Bearing failure | See service manual |

| Poor lubrication | Lubricate as necessary |

| Mechanical wear | See service manual |

Solvent characteristics

| Solvent | Polarity index | Refractive index (20°C) | UV (nm) cutoff (1 AU) | Boiling point (°C) | Viscosity (mPa.s; 20°C) | Miscibility with water |

| Acetic acid | 6.2 | 1,372 | 230 | 118 | 1,26 | 100 |

| Acetone | 5.1 | 1,359 | 330 | 56 | 0,32 | 100 |

| Acetonitrile | 5.8 | 1,344 | 190 | 82 | 0,37 | 100 |

| Benzene | 2.7 | 1,501 | 280 | 80 | 0,65 | 0,18 |

| Butylacetate | 4.0 | 1,094 | 254 | 125 | 0,73 | 0,43 |

| n-Butanol | 3.9 | 1,399 | 215 | 118 | 2,98 | 7,81 |

| Carbon Tetrachloride | 1.6 | 1,466 | 263 | 77 | 0,97 | 0,08 |

| Chloroform | 4.1 | 1,466 | 245 | 61 | 0,57 | 0,815 |

| Cyclohexane | 0.2 | 1,426 | 200 | 81 | 1,00 | 0,01 |

| Ethylenechloride | 3.5 | 1,444 | 225 | 84 | 0,79 | 0,81 |

| Methylenechloride | 3.1 | 1,424 | 235 | 41 | 0,44 | 1,6 |

| Dimethylformamide | 6.4 | 1,431 | 268 | 155 | 0,92 | 100 |

| Dimethylsulfoxide | 7.2 | 1,478 | 268 | 189 | 2,00 | 100 |

| Dioxane | 4.8 | 1,422 | 215 | 101 | 1,54 | 100 |

| Ethylacetate | 4.4 | 1,372 | 260 | 77 | 0,45 | 8,7 |

| Ethanol | 5.2 | 1,360 | 210 | 78 | 1,20 | 100 |

| Diethylether | 2.8 | 1,353 | 220 | 35 | 0,32 | 6,89 |

| Heptane | 0.0 | 1,387 | 200 | 98 | 0,39 | 0,0003 |

| Hexane | 0.0 | 1,375 | 200 | 69 | 0,33 | 0,001 |

| Methanol | 5.1 | 1,329 | 205 | 65 | 0,60 | 100 |

| Methylbutylether | 2.5 | 1,369 | 210 | 55 | 0,27 | 4,8 |

| Methylethylketone | 4.7 | 1,379 | 329 | 80 | 0,45 | 24 |

| Pentane | 0.0 | 1,358 | 200 | 36 | 0,23 | 0,004 |

| n-Propanol | 4.0 | 1,384 | 210 | 97 | 2,27 | 100 |

| Isopropanol | 3.9 | 1,377 | 210 | 82 | 2,30 | 100 |

| Diisopropylether | 2.2 | 1,368 | 220 | 68 | 0,37 | |

| Tetrahydrofuran | 4.0 | 1,407 | 215 | 65 | 0,55 | 100 |

| Toluene | 2.4 | 1,496 | 285 | 111 | 0,59 | 0,051 |

| Trichlorethylene | 1.0 | 1,477 | 273 | 87 | 0,57 | 0,11 |

| Water | 9.0 | 1,333 | 200 | 100 | 1,00 | 100 |

| Xylene | 2.5 | 1,500 | 290 | 139 | 0,61 | 0,018 |

0

0

0

0