Dryers and humidifiers

Dryers table - quick guide

Dryer table - quick guide for selection of dryer -basic parameters.

| Parameter / Model | MD | PD | MDH (heated) | ME | DM (portable) |

|---|---|---|---|---|---|

| Type | Single tube | Multitubes (50, 100, 200) | Single tube | Single tube | Single tube + dessicant |

| Nafion tube O.D. | 0,053", 0,072", 0,108" | - | 0,108" | 0,053", 0,063", 0,072", 0,108" | - |

| Nafion tube I.D. | 0,042", 0,060", 0,086" | - | 0,086" | - | 0,052," 0,086" |

| Available Lengths (inch) | 12, 24, 48, 72, 96, 144 | 12, 24, 48, 72 | 96 | 6, 12, 18 24, 36, 48 | 24 |

| Housing Materials | Stainless Steel or Fluorocarbon or Polypropylene | Stainless Steel or Fluorocarbon or Polypropylene | Flourocarbon | Polypropylene | - |

| Maximum Flow Rate | 200 ml/min, 2, 4 l/min depending of type | 4, 8 nebo 15 l/min depending of type | 1 l/min | 1,2 l/min | 0,5; 1 l/min depending of type |

Parameters and recomandation for dryers MD - dryer with one tube.

| Parameter | MD-050 | MD-070 | MD-110 |

|---|---|---|---|

| Nafion tube O.D. | 0,053" | 0,072" | 0,108" |

| Nafion tube I.D. | 0,042" | 0,060" | 0,086" |

| Available Lengths (inch) | 12, 24, 48, 72 | 12, 24, 48, 72, 96, 144 | |

| Housing Materials | SS, Flourocarbone, PP | ||

| Maximum Flow Rate | 200 ml/min | 2 l/min* | 4 l/min* |

* MD-070 and MD-110 offer approximately the same drying performance. Specify MD-110 when pressure drop is a concern, MD-070 to minimize dead volume. For higher fl ow rates, please see our PD-Series dryers.

Parameters and recomandation for dryers PD - dryer with more tube.

| Parameter | PD-050T | PD-100T | PD-200T |

|---|---|---|---|

| Number of nafion tubes | 50 | 100 | 200 |

| Available Lengths (inch) | 12, 24, 48, 72 | ||

| Housing Materials | SS, Flourocarbon, PP | ||

| Recommended Flow Rates* | 4 l/min | 8 l/min | 15 l/min |

* Flow rates based upon unheated, 24" dryer achieving a -10°C dew point.

Nafion dryers

Perma Pure LLC manufactures components and devices primarily designed to dry and humidify gas streams. The core technology is Nafion®, a Dupont co-polymer that is highly selective in the removal of water. Perma Pure manufactures Nafion into tubing of various diameters to optimize the transfer of water through the Nafion. The water moves through the membrane wall and evaporates into the surrounding air or gas in a process called perevaporation. This process is driven by the humidity gradient between the inside and the outside of the tubing. In addition to drying and humidifying, our products can be used as ion exchange membranes and specialty separation membranes that take advantage of the unique properties of Nafion.

Perma Pure LLC manufactures components and devices primarily designed to dry and humidify gas streams. The core technology is Nafion®, a Dupont co-polymer that is highly selective in the removal of water. Perma Pure manufactures Nafion into tubing of various diameters to optimize the transfer of water through the Nafion. The water moves through the membrane wall and evaporates into the surrounding air or gas in a process called perevaporation. This process is driven by the humidity gradient between the inside and the outside of the tubing. In addition to drying and humidifying, our products can be used as ion exchange membranes and specialty separation membranes that take advantage of the unique properties of Nafion.

What is Nafion?

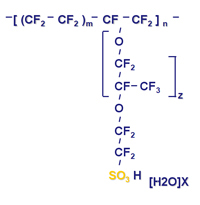

Nafion is a copolymer of tetrafluoroethylene (Teflon®) and perfluoro-3,6-dioxa-4-methyl-7-octene-sulfonic acid. Like Teflon, Nafion is highly resistant to chemical attack, but the presence of its exposed sulfonic acid groups confers unusual properties. Sulfonic acid has a very high water-of-hydration, absorbing 13 molecules of water for every sulfonic acid group in the polymer; consequently, Nafion absorbs 22% by weight of water.

Nafion is a copolymer of tetrafluoroethylene (Teflon®) and perfluoro-3,6-dioxa-4-methyl-7-octene-sulfonic acid. Like Teflon, Nafion is highly resistant to chemical attack, but the presence of its exposed sulfonic acid groups confers unusual properties. Sulfonic acid has a very high water-of-hydration, absorbing 13 molecules of water for every sulfonic acid group in the polymer; consequently, Nafion absorbs 22% by weight of water.

Unlike micro-porous membrane permeation, which transfers water through a relatively slow diffusion process, Nafion removes water by absorption as water-of-hydration. This absorption occurs as a First Order Kinetic reaction, so equilibrium is reached very quickly (typically with in milliseconds). Because this is a specific chemical reaction with water, gases being dried or processed are usually entirely unaffected.

Gas Dryers and Humidifiers

Gas Dryes

Gas Dryes

Gas dryers are commonly used in analytical instruments such as gas chromatographs, thermal desorbers, etc... They also are used in sample conditioning systems, where is a need of water removal from gaseous samples to avoid water condensation in sample lines and in gas analysers.

- Nafion dryers - details

- Nafion dryers - products

- Nafion dryers - table quick guide

- Adsorption dryers

- Gas coolers

Humidifiers

Humidifiers are mostly used in medical devices and in calibration systems, where is a need to supply a gas of stable humidity. New area where gas humidifiers are used is micro-fuel cells as a power sources. These micro-fuel cells require humid hydrogen and Nafion dryers are the best choice for this purpose.

0

0

0

0